Home >> Product >> Crane Rail

Looking for a robust and reliable crane rail solution? Look no further than the U71Mn QU70 Rail, proudly made in China to deliver exceptional performance and durability.

Material: U71Mn

Weight:52.8Kg/m

Length:12m

Standard:YB/T5055-2014

The U71Mn Rail Specification sets the standard for excellence in heavy-duty applications. Manufactured with precision engineering and utilizing high-grade U71Mn steel, this rail offers superior strength, load-bearing capacity, and longevity. It is designed to withstand the most demanding environments, ensuring reliable and efficient operations.

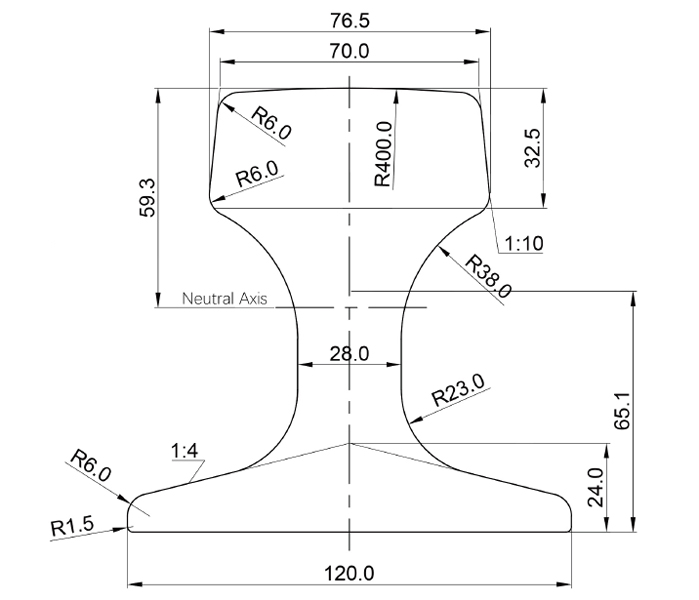

| Parameters | |||

| Type | weight (kg/m) | material | length (m) |

| QU70 | 52.80 | U71Mn | 12 |

| rail height (mm) | bottom width (mm) | head width (mm) | web thickness (mm) |

| 120 | 120 | 70 | 28 |

Equally impressive is the Qu70 Rail Specification, which highlights its unique characteristics and suitability for a wide range of industrial applications. With precise dimensions and a tailored design, the Qu70 Rail offers optimal support for cranes and heavy machinery, ensuring smooth and efficient material handling operations.

| Crane Rail | Size | Rail Height | Bottom Width | Head Width | Web Thickness | Weight kg/m |

| QU70 | 120 | 120 | 70(76.5) | 28 | 52.80 | |

| QU80 | 130 | 130 | 80(87) | 32 | 63.69 | |

| QU100 | 150 | 150 | 100(108) | 38 | 88.96 | |

| QU120 | 170 | 170 | 120(129) | 44 | 118.10 |

The U71Mn QU70 Crane Rail combines the best of both worlds, incorporating the exceptional qualities of U71Mn steel and the superior design of the Qu70 Rail. This winning combination provides a rail solution that surpasses expectations in terms of performance, reliability, and longevity.

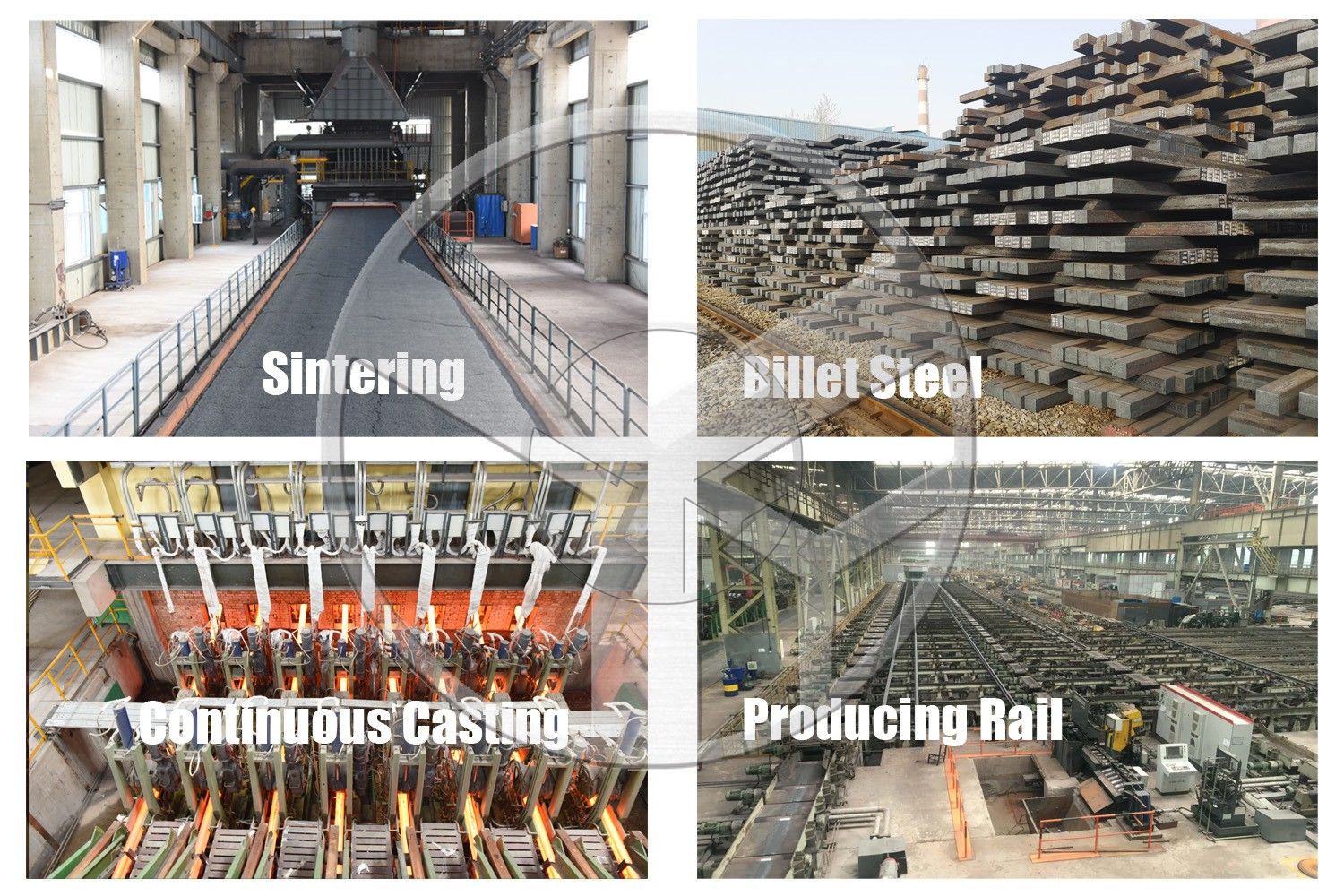

As a leading manufacturer in China, YONGYANG takes pride in producing crane rails that adhere to the highest industry standards. Our commitment to quality and customer satisfaction ensures that you receive a product that exceeds your expectations.

Experience the exceptional performance and reliability of the U71Mn QU70 Crane Rail today. Contact us to discuss your specific requirements and discover how our superior rail solution can elevate your industrial operations to new heights.

Application:

Steel rail, also called rail track, or steel track, is the main component of railway track. Its function is to guide the wheels of the locomotive, bear the great pressure of the wheel, and keep the stability of railway transportation. The rail must provide continuous, smooth and minimum rolling surfaces for the wheels. In an electrified railway or automatic block section, rail can also be used as an orbital circuit.

The steel rail in China is divided into Crane rail, Heavy rail and light rail.

Here's a table comparing the differences between crane rail, heavy rail, and light rail:

| Crane Rail | Heavy Rail | Light Rail | |

|---|---|---|---|

| Purpose | Specifically designed for crane and heavy-duty material handling applications | Mainly used for railway tracks and transportation of heavy loads | Primarily used for urban transit systems, trams, and light-duty applications |

| Load Capacity | High load-bearing capacity to support heavy machinery and cranes | Moderate load-bearing capacity for freight and passenger trains | Lower load-bearing capacity suitable for light vehicles and transit systems |

| Profile | Wide and flat profile, often with asymmetrical designs to accommodate crane wheels | Standardized profile with a consistent design for railway tracks | Narrower profile, optimized for urban transportation and smaller vehicles |

| Material | High-grade steel for enhanced strength and durability | High-quality steel to withstand heavy loads and railway traffic | Lightweight materials such as aluminum or composite materials for improved energy efficiency and maneuverability |

| Usage | Mainly used in industrial settings like ports, construction sites, and manufacturing facilities | Predominantly employed in railway networks for the transportation of goods and passengers | Primarily utilized in urban areas for public transit systems and light transportation |

| Track Maintenance | Requires specialized maintenance due to heavy-duty usage and higher stress levels | Regular maintenance and inspection are required for railway safety and operational efficiency | Relatively easier maintenance due to lighter loads and simpler systems |

| Applications | Material handling, crane operations, heavy machinery transport | Freight and passenger train transportation | Urban transit systems, trams, light-duty transport |

Note: The table above provides a general overview of the differences between crane rail, heavy rail, and light rail. Please note that specific specifications, profiles, and applications may vary depending on the region and industry standards.

In China, the Crane rail includes QU70, QU80, QU100 and QU120. which also called ISCR70, ISCR80, ISCR100 and ISCR120 Crane rail in India. In Russia, it is called KP70, KP80, KP100 and KP120 Crane rail.

Crane rails are designed for carrying heavy loads and are used in the laying of crane tracks for port building. Compared with the railway's heavy rail, the crane rail height is low and the head width thick waist size is bigger.

Whether you require crane rails for port facilities, construction sites, or manufacturing plants, the U71Mn QU70 Crane Rail is the ideal choice. Its impressive specifications and robust construction make it suitable for heavy-load applications, ensuring seamless and safe material handling operations. Get a Free Quotation.

Leave a message