Home >> News >> Latest News

1. Feeding: The performance of incorporating hot metal or scrap metal into the electrical furnace or converter is step one in the steel manufacturing operation.

2. Slag formation: The performance of correcting the slag composition, alkalinity, and viscosity and its response capacity in iron and steel manufacturing.

3. Slag release: The slagging or slag surgery taken throughout the smelting process based on distinct smelting requirements and functions during electric arc furnace steelmaking.

4. Molten Pool Stirring: Providing power into the molten metal pool to induce motion of molten metal and slag to enhance the kinetic states of the metallurgical response.

5. The molten pool agitation can be accomplished by way of mechanical, gas, electromagnetic induction and so on.

6. Dephosphorization in iron: The dephosphorization response is performed in the port between slag and phosphorus-containing molten iron.

7. Electric furnace bottom blowing: The gas is blown to the pool of this furnace in line with the procedure demands through a nozzle positioned in the base of the furnace to quicken the melting and encourage the metallurgical reaction procedure.

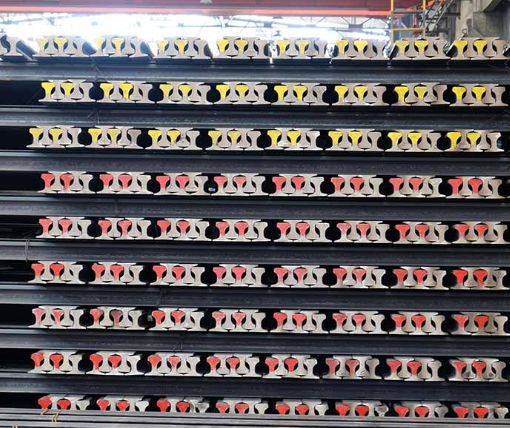

We are China Standard Heavy Steel Rail Manufacturer and Crane Rail Manufacturer. If you are interested, please contact us.

Previous: Christmas Promotional Products

Leave a message